MOM is the real-time software layer that links product lifecycle management (PLM) to automation, connecting the virtual world of product development with the real world of production.

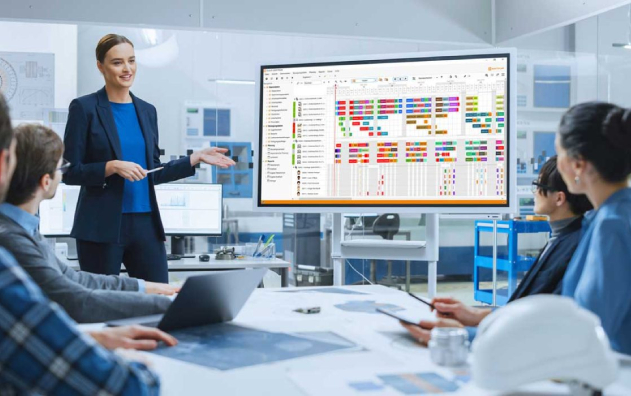

Digitally plan and orchestrate manufacturing and quality operations for more efficient production, improved reliability and better visibility into operations.

Compare as-planned and as-is data to improve innovation and quickly implement change. Transform big data into actionable intelligence to predict and solve issues.

Enable the digital enterprise with industry-rich MOM applications that help you cost-effectively make the highest quality products faster than your competitors. Opcenter" is a suite of Manufacturing Operations Management (MOM) applications developed by Siemens Digital Industries Software. It is designed to address various aspects of manufacturing operations, providing solutions for production planning, execution, quality management, and performance optimization.

Opcenter APS software can be used for long-term strategic planning (months and years), mediumterm tactical planning (weeks), and for detailed sequencing and scheduling.

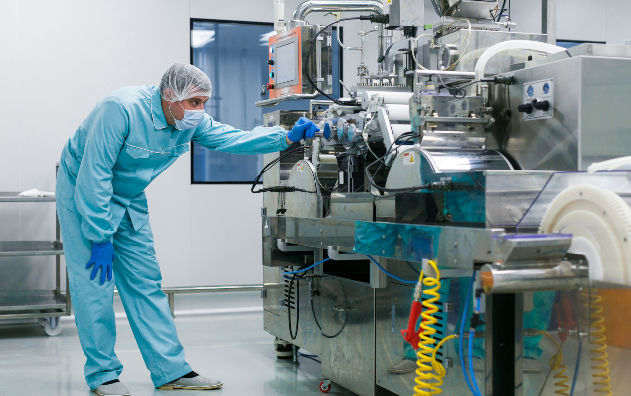

Opcenter Quality is a closed-loop quality management system (QMS) family of products that safeguard compliance and drive continuous improvement for high-quality products.

Orchestrate complete visibility, control and optimization of manufacturing operations to build final products that accurately reflect design, engineering and process data

The Opcenter Research, Development and Laboratory (RD&L) family of software products streamlines, optimizes and aligns formulated product R&D, driving innovation efficiency and data management for consumer-packaged goods

Opcenter Intelligence supports faster, better decision-making, with manufacturing intelligence and actionable insights that bring processes under control. Achieve, Optimize production quality gain global visibility, and boost productivity.

Opcenter Connect integrates Opcenter systems with enterprise resource planning (ERP) systems, manufacturing systems with cloud intelligence systems, Opcenter systems with manufacturing shop floor devices or tools, and much more.

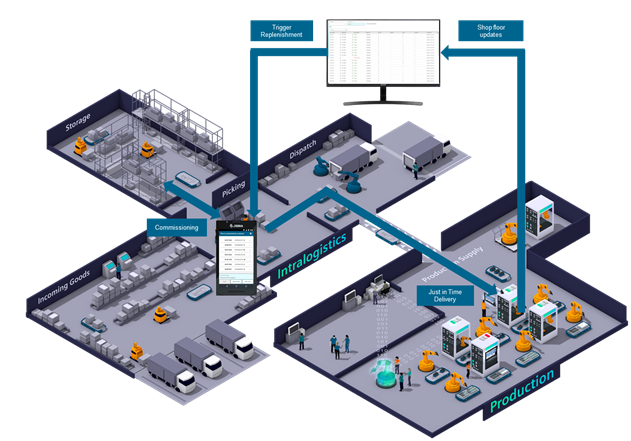

With Opcenter Intraplant Logistics, you can increase line performance, maintain inventory accuracy and ensure smooth material flow between the warehouse and the shop floor with advanced intralogistics capabilities.